- Cartridge Heaters of diameter Ø 3.0 to Ø = 50 with a maximum length of up to 3000mm

- Temperature-tight to a maximum of 750 °c on the cartridge sheath

- Special Watt power up to 60 w/cm ²

- Voltages 3V to 500V

- Reproducible Power Distribution possible

- available as PTC controlled cartridge heater from Ø10,0mm

- with integrated limiter available from Ø16.0mm

- Multiple switchable zones according to customer requirements

- Ground version also possible for long cartridges

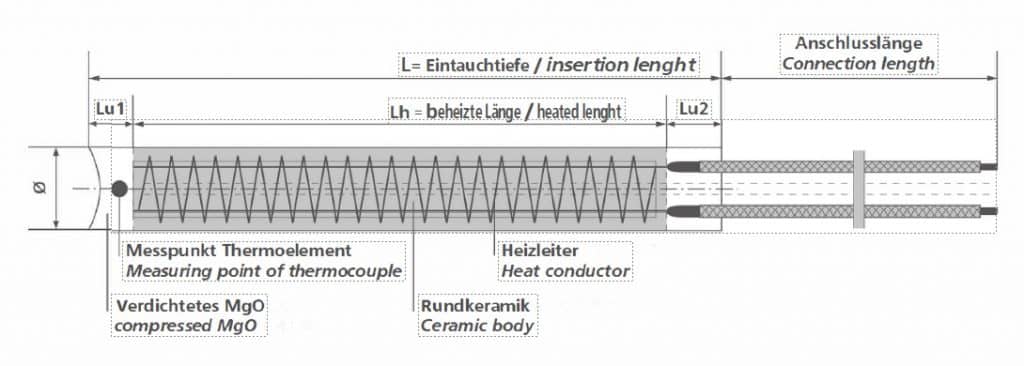

- With integrated temperature sensor type J, K, PT100 position selectable

- UL approval possible for many designs

| Metric | Inch | Square |

| Ø 3, 0mm | Ø 1/4″ (6,35mm) | ▇ 8.0 x8, 0 mm |

| ؠ4, 0mm | Ø 5/16″ (7,95mm) | ▇ 10.0 x 10, 0mm |

| Ø 4, 5mm | Ø 3/8″ (9,52mm) | ▇ 20.0 x 20, 0mm |

| Ø 6, 5mm | Ø 1/2″ (12,70mm) | ▇ 20.0 x 10, 0mm |

| Ø 8, 0mm | Ø 5/8″ (15,90mm) | ▇ 20.0 x 15, 0mm |

| Ø 10, 0mm | Ø 3/4 ″ (19, 05mm) | ▇ 25.0 x 25mm mm |

| Ø 12, 5mm | Ø 1″ (25.40mm) | ▇ 15.0 x 15, 0mm |

| Ø 14.00/14, 85mm | ||

| Ø 16, 00mm/18, 00mm | ▇ 1.8 x 3.2 mm | |

| Ø 20.00 MM | ▇ 2.2 x 4.2 mm | |

| Ø 25.00 MM | ▇ 3.0 x 3.0 mm | |

| Ø 31.70 MM | ▇ 4.6 x 8.6 mm | |

| Ø 34.00 MM | ▇ 4.5 x 4.5 mm | |

| Ø 50.00 mm |

Explosion proof cartridge heaters

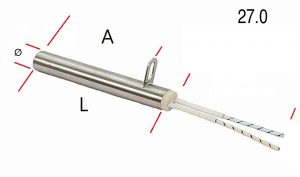

Technical possibilities and variants

- Maximum permissible surface load 18 W/cm²

- Operating temperatures corresponding to temperature classes T1 (≥ 450 °C) to T6 (85 °C)

- Application area: Zone / Medium: 3G/3D

- Explosion group: Zone 2: IIIC

- Optionally with integrated thermal sensor type K

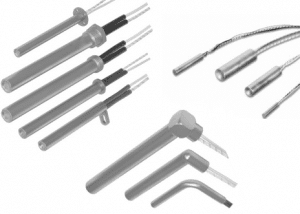

- Construction: straight or angled

- Diameter: 9.5-25.4 mm

Areas of application

- Explosive manufacturing processes of zone 2 (gas), zone 22 (dust) of equipment group IIC, IIIC

- Coat material Stainless Steel

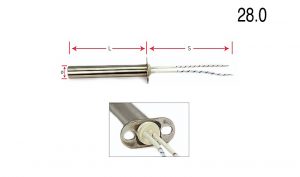

- Diameter tolerance standard up to 300mm length -0.02/-0.06mm

- Length tolerance ± 1.5%

- Power tolerance ± 10%

- High Voltage fixed to 1500V (depending on diameter)

- Insulation Resistance > 5MΩ

- Operating temperature max. 750 °c

All tolerances and performance specifications can be restricted on request.

Product example

Individual designs according to customer requirements

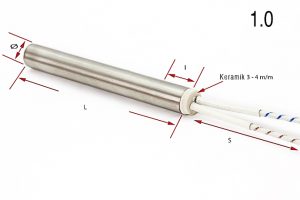

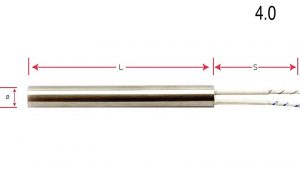

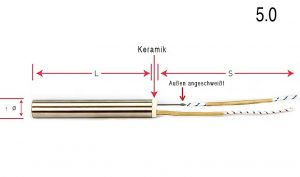

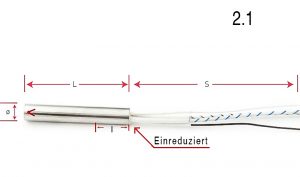

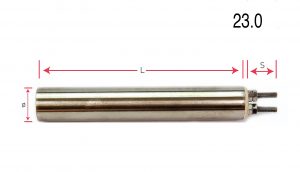

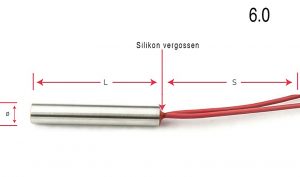

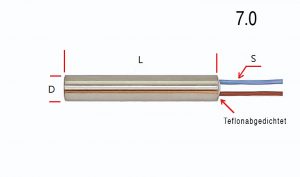

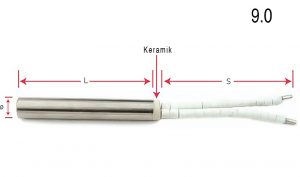

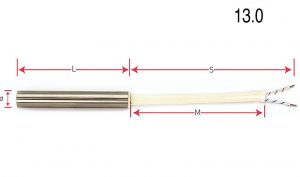

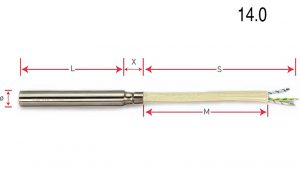

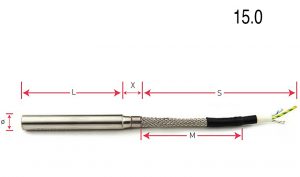

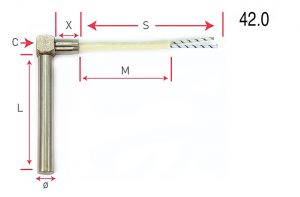

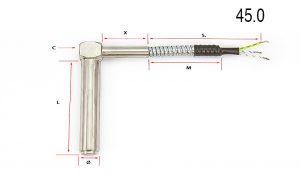

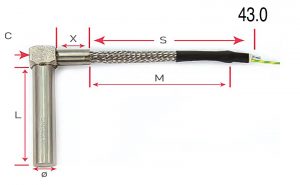

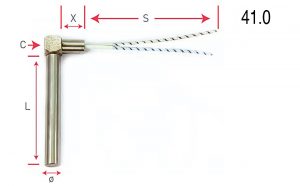

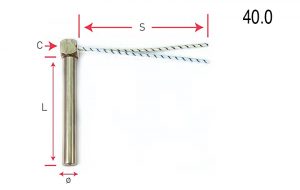

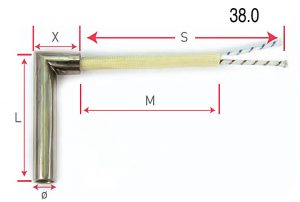

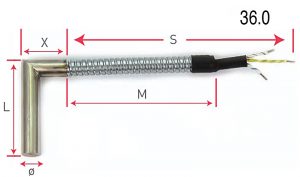

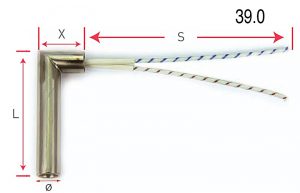

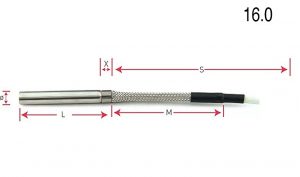

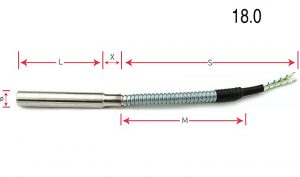

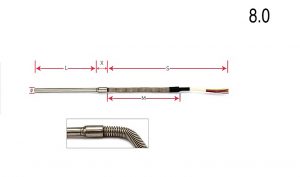

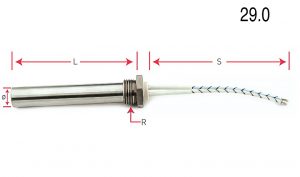

Selection of connection types for cartridge heaters

Angle block 90° glass silk protection

Download table

Angle block 90° with corrugated hose

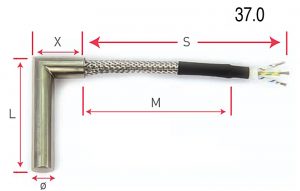

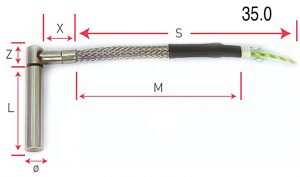

Angle block 90° with wire mesh hose

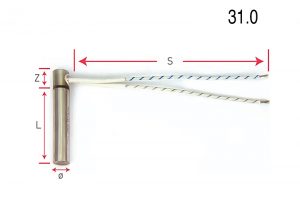

Angle block 90° with pipe piece + strands

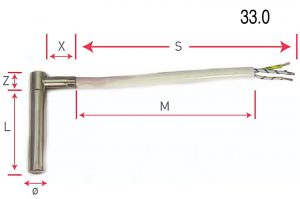

Angle block 90° with strands