Screw-in heating elements configurator

HKE-tec screw-in heating elements made of stainless steel and copper are ideal for heating liquids and gases. They are simply screwed into containers or pipes.

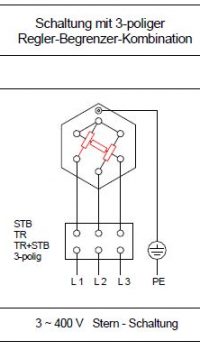

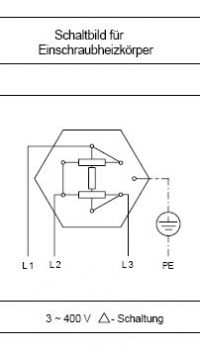

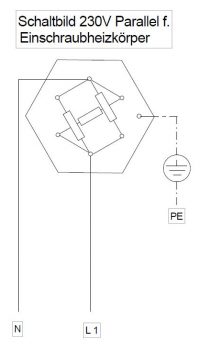

Depending on your needs, they are made of pure stainless steel and can also be welded. There are different switching options such as star or delta. The tube diameter and material are application oriented.

UL certified heaters available upon request.

Screw plug tubular radiators from HKE-Tec can be obtained without caps, with plastic caps or metal caps.

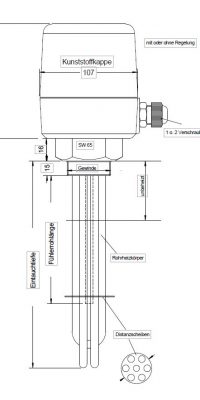

Plastic cap with or without control

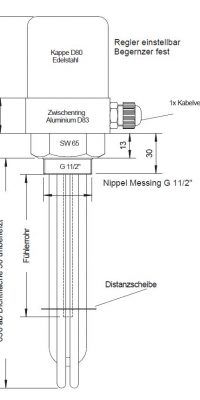

Stainless steel cap with control

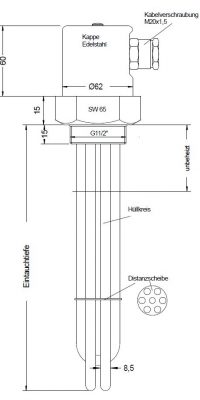

Stainless steel cap or aluminum cap

Up to 6 heating elements (depending on the size of the nipple) soldered/welded in a threaded nipple, held together by one or two discs, depending on the immersion depth

Coat Material: Stainless steel or copper

Tube Diameter: 6.5/8.5 or 16.0 mm

Threaded Connection Bolt:

M3 for Ø 6.5

M4 for Ø 8.5

M6 for Ø 16.0

Connection version:

Connection box with temperature controller or limiter

Possible mounting/connection thread:

Thread Nipple m 45 or M 77 as well as 1 ½ ″, 2 ″ or 2 ½ ″

Surface loads:

10 w/cm ² water heating in Continuous heaters

8 w/cm ² water Heating of Moving media

4 w/cm ² water, cleaning bath, heating dormant

2 w/cm ² Light flammable oil, or for gas heating

Print Security:

Up to 15 bar

Voltage:

24V/230 V/400V

Electrical test according to regulations DIN VDE 0700

Performance tolerances: + 10%/-5%

High-voltage strength: 1,250 Volts/1 min

Isolationwiderstand: > 5 MOHM

Comment:

- Care must be taken to ensure that the heated length is covered by the entire medium to be heated.

- In all cases, the thermal expansion of the heating element must be taken into account in terms of room requirements.

Use of the screw-in heating elements

Our screw-in tubular heating elements have different surface loads. Please consider the following limit values when making your selection:

Surface load 2-3 W/cm2: Heating of oil or light grease, e.g. in hydraulic power units

Surface load 4-5 W/cm2: Heating of water or air at a speed of at least 4 m/sec., cleaning and degreasing baths

Surface load 8-9 W/cm2: Heating of fresh water in boilers, running water at a pressure of less than 6 bar

Heat losses

The following empirical values are added to cover the heat losses:

For radiation and convection

20% to 30% for non-insulated containers,

10% to 20% for insulated tanks,

Heat loss for open containers by evaporation

Final water temperature Heat loss per m2 water surface in kWh

40˚C 0,6

60˚C 2,8

80˚C 7,0

95˚C 15,0

The power for the heat of fusion or evaporation shall be added when a substance is melted or evaporates. This power is calculated from the mass (kg) multiplied by the heat of fusion or evaporation in (Wh/kg). In the case of temperature controlled equipment, the heating power may be set at twice the calculated power.

Please note:

Hard water causes lime deposits on the heating elements and can lead to overheating of the heating elements. Calcification can be reduced by reducing the surface load. Water containing free chloride ions also shortens the life of the heating elements.

Product example